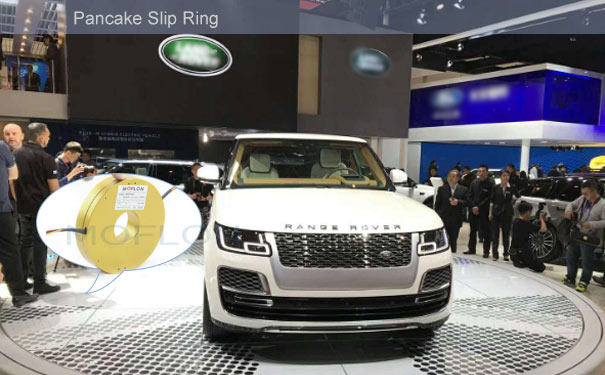

slip rings have a number of varieties. Each variety has different uses and are applied in various fields. The pancake slip ring is one of such variation. It is a flat-shaped disc in which the conductors are centrally placed on the rotating shaft, and the axial length is reduced.

The utilization of this slip ring for other application is limited for its shorter height. It is mainly used in the sectors like the textile, medical, print, and also in the areas of measure and test.

Some features of the pancake slip rings are:

1)Heavier: The flat-shaped slip rings have more weight.

2)Large dimension: The dimension of the slip rings is much larger.

3)More capacity: The slip rings have the capacity to handle the current and signal transmission from the stationary structure to the rotary body.

4)Workable brushes: The quantity of wear of brushes is quite good. The positive brush has less rate of wear than the negative brush.

5)Wear debris: The vertical axis collects more wear debris after running for a long time.

6)Low noise and contact resistance: The slip rings have a better outcome for the fine brass rings combined with other metal rings. It produces low noise and has less contact resistance.

7)Good for slow-moving speed: This slip ring is good for slow-moving speed when connected with brass rings.

8)Free of maintenance: The flat disc is free of maintenance.

9)Low torque: The other feature of the flat slip ring is that it makes low torque.

10)High stability and reliability: The pancake rings consist of precious metal wire which has high stability and reliability.

The slip ring assemblies are composed of stator and rotor which is connected to the sensors, for example, accelerometers. The rotor is attached to the rotating shaft that connects with the stator. The signal transmits from the sensors through the rotor component to the stator component.

As these assemblies are designed in a simple way, it is much easy to shoot out the mechanical problem, noise, and quality issues. It is widely used for communication and supplying power to the Programmer Logic Controller and in the electronic units like the automatic and robotics industry.

slip rings are made of different types on the basis of purpose and capacity. Like the hydraulic slip ring is manufactured for the vacuum cleaner, AC, and gas industry. This ring can connect with 1 ~ 128 electrical wires to supply the current and signal through the joints.

Following are the chief characteristics of the hydraulic slip ring:

1.Custom-made: The hydraulic rings are custom-made following the request of the customers and technology.

2.Quality: High quality of gold and gold fiber brush contact is used to make the slip rings.

3.Low cost: The slip rings are made of low cost.

4.Reliability: These slip rings are reliable as these are manufactured of good quality.

5.Less noise: The hydraulic rings emit less noise.