The slip ring motor is generally referred to as phase wound motor which is quite commonly used in almost all sectors. They are designed in such a manner that they can be initiated with a full line voltage supply across. The full voltage has to be supplied across terminals which makes the entire process of transmission possible.

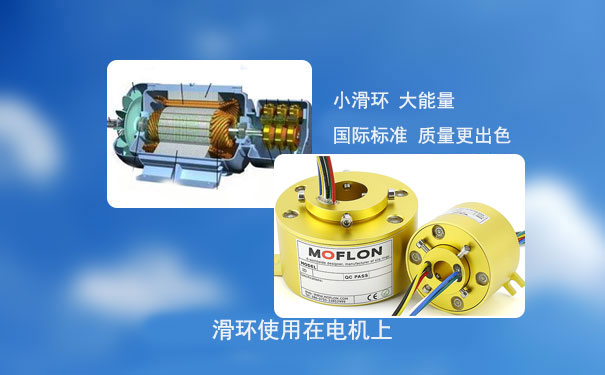

The wound rotor containing the rotor winding terminals are attached to a slip ring which is mounted on the shaft, but at the same time, they are insulated separately from the shaft. The lead connection fitted to the slip ring along with the brush pressing on the ring is exposed to external resistance.

Adjusting the flowing of current

During the initial phase of operation, the flow of current in the motor is maintained by adding external resistance to the circuit which proves to be quite useful to avoid excess thermal heat with which usually caused by the rise of temperature.

Torque stabilization

Now after the initial phase of maintaining the electric current balance as the rotors speed up its operation the level of external resistance is brought down bit by bit. This step to reduce the external resistance influx is taken to stabilize the level of torque, especially, when the rotor enters the second clause where it begins to gain acceleration.

The final stage

In the last phase when a stable torque level has maintained the supply of external resistance is completely cut off. This is brought down to allow the rotor to gain full load torque with the reduced involvement of the slip ring.

One of the important points to note in this entire operation is that the slip which is evidently required to generate a maximum level of torque is for. a matter of fact directly proportional to the rotor resistance. Thus, as the external resistance passing on to the slip ring rotor is increased the level of torque consequently increases and vice versa.

The design pattern of a slip ring motor

During, the initial rotational phase the slip ring technology included in the system failed to increase the efficiency of the motors, but with time the slip ring manufacturers came up with innovative structural changes that made the slip ring motors as a while more effective. The commonly used slip ring induction motor or wound rotor motor now come with a variation of the stator that resembles as the squirrel cage induction motor. In this case, the application of slip ring is considerably different. Here, the slip rings which are closely associated with the rotor windings are not introduced to initiate the flow of current. In fact, they are brought in the system to induce resistance in the series as and when the rotor windings start its initial operation.

The entire conventional application of slip ring for allowing the flow of current and signals is put to rest in the slip ring based motors. This, we stress on the various functionality of aspect of the slip ring which is set have more new components as the technology progresses in near future.