The pancake slip is a special type of slip ring that used in equipment with a constraint on vertical/height space. As a result, addition of the conventional slip ring is not possible. Thus, the pancake slip ring provides a solution for with vertical space problem. However, it does not mean that this kind of slip ring doesn't come in different size variant. In fact, slip ring suppliers have been pushing larger pancake slip ring in the market as it is an important component for the reclaimers used in bulk material industry and many more such fields.

The pancake slip ring comes with a through bore size of 500mm - 1000mm. As mentioned earlier, this kind of slip ring is available with a larger diameter. The addition of new elements is the main reason behind the increasing diameter of the slip ring unit and they are known as split pancake slip ring. The pancake slip rings are used in various fields such as medical and textile.

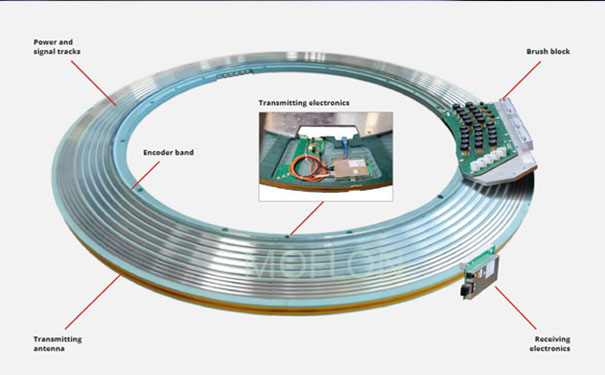

A pancake slip ring can be classified into two different parts, the separate disc, and the integral disc. This kind of slip ring has a known advantage of thinner thickness as compared to the through bore slip ring. Having said that, such slip rings can only be developed in the radial direction and not in the axial direction as it is structured in the form of radical direction.

The lack of development in the axial direction causes the average pancake slip ring to have a larger diameter which presents itself as a potential drawback. Though, such slip rings are thinner in size which might be perceived as an advantage, with a larger diameter it brings into platter a lot of challenges issues not only for the users but also for the slip ring manufacturer as they have been trying to amend things.

The efforts placed in by the research and development team have brought in the scheme of things an ultra-miniature pancake slip ring. This innovation eliminates the aforementioned problems and provides the user with light, thin, and upgraded version of the ordinary pancake slip ring.

Application of pancake slip ring

A pancake slip ring is applied in the various field, which ranges from manufacturing to medical. Thus, the diversity in application of such slip ring is unparalleled. Some of the application of pancake slip rings are mentioned below.

1.The processing and manufacturing equipment used in industry.

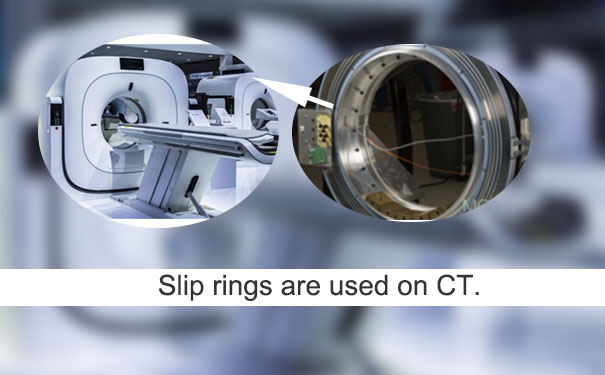

2.As mentioned, the use of pancake slip ring is more pronounced in medical equipment.

3.They are also in various equipment such as a rotary table, reel wheel, CNC (Computer Numerical Control) machine, and pallet machine.

4.It is also used in rotary sensors, magnetic drivers radar, and emergency lights.

One of the important things that need our attention here is the fact that the aforementioned varied application of pancake of slip ring is largely due to the inclusion of an ultra-miniature version of the same. So, the way moving forward the use of such slip rings will see a rise and with new technology cue being included, we might see an increased application of pancake slip rings.