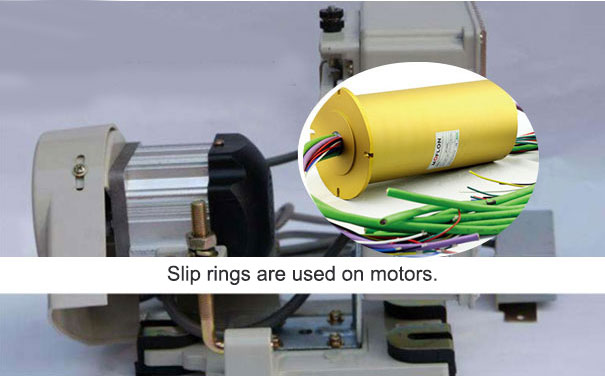

A slip ring is an electromechanical tool that helps in the transmission of electrical signals and power from a stationary structure to a rotating structure. It is the main medium of transport for the data and signals through the electric motor that is connected with a shaft and rotates with the same and the electric is passed on with the help of the fixed brushes.

The slip ring manufacturer considers a number of the factors based on which these electrical devices are made. It has various purposes and types which is highly considered while manufacturing the slip ring. The rotating electrical slip ring connector is provided for the long-lasting performance with minimum maintenance. It can be a great compatible op[tion for an induction motor slip rings.

Before we know about the slip ring induction motor application, let under what it stands for.

An induction motor is a type of wound rotor motor, in which the rotor winding is connected to an external resistance via the slip rings. The induction motor slip ring has a stationary structure which is designed resembling a squirrel cage motor, only the rotor is brought out with the insulated windings through brushes and slip rings. There is no application of power to slip rings during this phase. The main purpose of this, however, is to allow the resistance that can be placed in a series with the rotor windings while starting the wound rotor.

Now that we know what a slip ring induction motor or the wound rotor induction motor is, here are some of the roles that the induction motor has to play.

Applications of the wound rotor induction motor

The wound rotor motors are extremely compatible with the high starting torque that requires a lot of loads. A low starting current is also required for which it suits the same.

The slip ring induction motor is suitable for the high inertia loads, which results in the high losses of the energy.

For the loads that require a sudden build-up of the torque, it can be extremely reliable.

These are also used in the cranes, conveyors, pumps, compresses, and elevators.

The efficiency for a maximum torque of about 200 percent full loading value is around 90 percent. On the other hand, a fully loaded slip can be as low as around 3 percent.

There are many cage induction motors that are available in the markets, which can meet the demand of many industrial applications and several starting and working condition requirement. These can be classified as different classes. In short, it consists of the A class motors, B class motors, C class motors, and D class motors. These classes vary on the basis of the starting torque (whether high or low), starting current, and the operation of the slip.

These induction motors or wound motors are extremely suitable for driving irregular loads that require a frequent acceleration and a high loading. By the time these motors start driving the various high load, it is combined with a flywheel that can provide a kinetic energy.