The proper maintenance of a machine ensures, that the machine runs smoothly and stays in good condition and ensures the long life of the equipment. Preventive maintenance procedure does not require the machine to be dismantled. the most crucial part of a conductive ring and brush, if not maintained properly the entire functioning of the slip ring can be put to a standstill. The slip ring suppliers have actively engaged in putting forward the set of steps for maintenance which is mentioned below. The maintenance steps are divided into two different categories, the first in the list is general steps for maintenance, while the second category deals with maintenance aspect related to core electrical machine.

General steps for maintenance

The general steps for maintenance begin with inspecting the machine both during its operation and when the machine is not in active use. This set of operation of has to been done repeatedly to gather a data based on which the faults of any kind is brought to notice. For an instance, in some cases, the time differences are noted in relation to the time taken by the machine to start and gain full acceleration, while the data gathered during the operation is compared to ascertain any fluctuation in the speed with which the device operates.

Secondary steps like employing a regular cleaning schedule to avoid any kind of dust accumulation, which is often the case with the machines that are well maintained. The dust accumulation may seem to be a smaller surface on the surface but it takes a toll on the performance of the brush. As the sliding connection between the slip ring and brush cannot be maintained properly. Some of the other measures include checking any kind of disposition of the components. This can be done by observing various forms of patterns and marks on the shaft.

Maintenance for core electrical machine

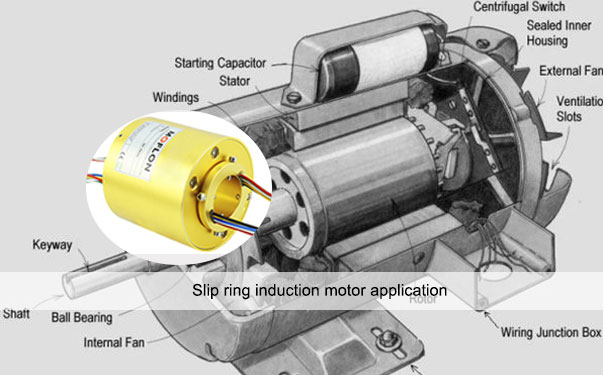

In case core electrical machine and by core electrical machine, we refer to that equipment which requires a set of slip ring which could transmit multiple signals during the rotational motion. In such equipment, there are two key important factors which need to be properly checked. The first is the insulating material used in the external surface of the slip ring. The inspection of insulating material begins with ascertaining the one that fits the situation in hand. As in some the amount of electric load passing through the system requires a certain level of resistance as in case of the slip ring induction motor, while in other cases resistance necessarily brings down the performance level of the device. Second and the final aspect which needs to be taken care of the greasing and the air gap between the internal bearings, the slip ring manufacturer have set certain standards for an air gap. And with the proper inspection of the deviation of the real-time air gap can be ascertained.