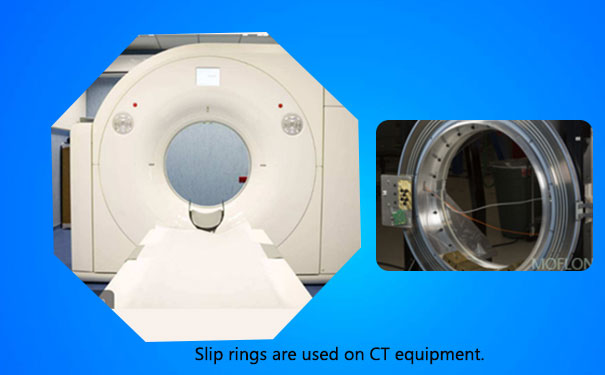

There has been a drastic increase in the use of slip rings in many industries. The use of slip rings has achieved a miraculous breakthrough in the field of medical applications. The devices used in the medical instruments used need to be very precise and compact so that they can be used efficiently and operate in constricted or limited spaces. This is achieved with the help of the electrical slip ring. Like many industries, they have become a crucial part of the medical industry too.

Application

The difficulties in the field of medical science have been taken care of by the help of slip rings and there have been many breakthroughs in this field. The slip ring or multiple slip rings are used in combination to achieve the desired result from the device. The slip ring devices are required to provide a very precise and accurate output of the signals so that the output of the operation of the concerned devices they are connected achieve a flawless result. The electrical noise and vibration of the equipment are less and this reduces the loss of transmission less and makes them more suitable as precision instruments. They also have a long service life and so are durable and can be used without maintenance for a long time. The use of slip rings in the medical industry has increased for these reasons. As in case of a life and death situation, precision tools and their durability can make the difference.

Advantages

The slip rings used in the medical industry are capable of transmitting both digital and analog signals and are very compatible Data Bus Protocol. The slip rings have the integration of power, signals, and frequency into one single unit this make it more compact and available for use in space-constrained environments. The contacts used in the slip ring assembly unit are made of advanced fiber brush technology which reduces the electrical noise and allows precise and accurate transmission of data. This is also facilitated as the brushes have a low contact resistance and the pressure of the contacts on the conductive rings is low resulting in low friction.

The low friction helps in reducing the wear of the contact brushes and in turn, reduces the generation of debris. This generation of debris causes the corrosion of the surface of the conductive rings and this leads to vibration of the equipment internally and in worst cases dislocation the rings causing a stop to the operation of the device. Since the internal corrosion and the replacement of the internal parts is not required, it makes the arrangement maintenance free and also provides a long life to the device.

There are many advantages in the use of the slip rings due to their accuracy and efficiency in the transmission. They have become an integrated part of almost every machine in the medical industry. Their usage increases day by day as the requirement of the industry grows. It can be very well be expected that we soon may see many other applications of these slip rings.