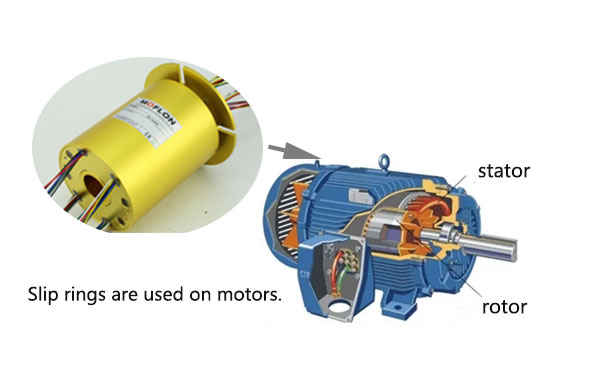

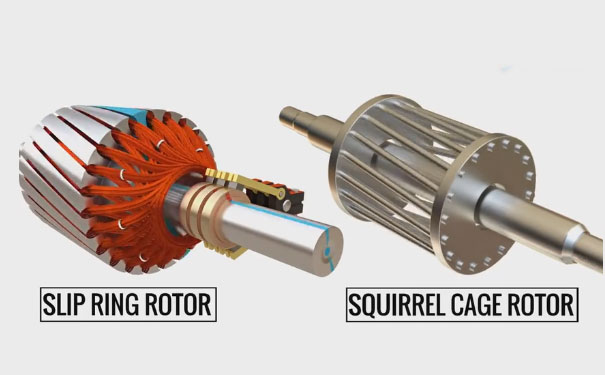

The slip ring induction motor as discussed earlier is made up of two key components the stator and the rotor. The structure of stator does not vary a lot, but it is the formation of a rotor that makes all the difference. Just a quick recap, a three-phase wound rotor is added to the rotor, aging has three phase setup and contains an evenly distributed came wire windings. Now, one end of the winding wires are internally stacked as we all know, but the other end is connected to three different slip ring.

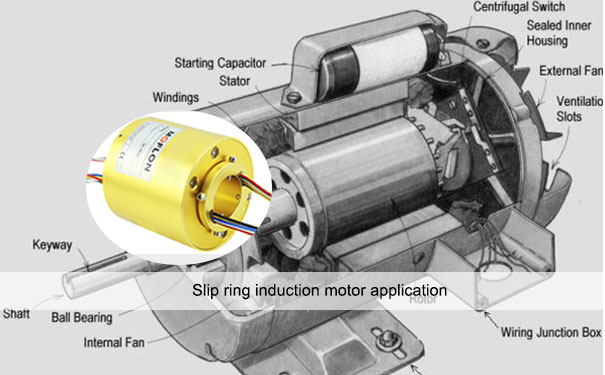

The manner in which the terminal end of the wire is connected to slip ring is something that is subtle but yet makes a big difference in complying with the standard application of slip ring induction motor application. The terminal end of the wire as said earlier is connected to three different slip rings, which in turn is mounted on the shaft of the rotor itself. Now, the terminal end of wires makes the connection. With the slip ring with the use of carbon brushes. The slip ring and the brush are held together with the slip ring assembly.

Carbon brush and rheostat connection

The carbon brush which is used to make the connection between the slip ring and the other end of the wire is further connected to a rheostat with a three-phase connection. It is the combination of the external rheostat and the slip ring that the first place makes the entry of resistance in the rotor circuit possible. With the addition of a higher level of resistance during the initial phase allows for a higher torque level which gradually increases over time as the rotor advance through the different phase of operation.

Operational pattern under the normal working condition

In the normal working conditions, a metal collar is used to achieve the automatic shirt circuitry form of the slip ring. To obtain such as a state using the metal collar, it is pushed through the shaft which results in the connection between the slip ring.

The entire operation of slip ring motors combination with slip ring and brush does bring into the system a certain rate of friction. Thus, to avoid such friction the brush units are automatically lifted. It not only limits the level of friction, but it also helps in cutting down the friction loss. It also becomes important to highlight the fact that the working of a wound rotor is quite similar to the working of the squirrel cage motor.

Having discussed in the entirety about the combination of the slip ring, brush gear, and the rheostat. Let us look at some of the advantages of a slip ring induction motor.

The most pertinent advantage of the slip ring induction motor is raw with which the rotational speed can be controlled.

The use if will ring induction motor can bring into the system a high level of pull out torque even with an absolute zero RPM.