With the rapid development of online monitoring technology, more and more data transmission applications between rotating equipment and fixed equipment (motors, generators, radars, etc.) have traditionally adopted mechanical multi-channel slip rings to fix the rotating parts. Partially connected for data interaction. The performance of the technology slip ring itself has certain limitations, such as friction torque, short life, and poor anti-electromagnetic interference capability.

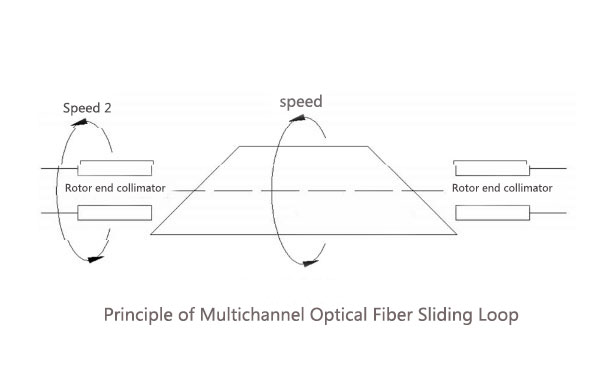

With the rapid development of optoelectronic technology, a new fiber optic slip ring has been developed. Compared with the technology slip ring, the fiber optic slip ring has no friction, long life, no electromagnetic interference, no crosstalk and no radiation, but the fiber slide The ring also has a fatal shortcoming.

The optical transmission requires extremely high direction. The slip ring must have a precise structure, and the rotating device vibrates greatly, resulting in difficulty in light alignment, large loss, and unstable transmission. At present, most of the optical fiber slip rings used in China are imported products, and only a few manufacturers in China can develop reliable and practical products.

In addition, the technical slip ring and the fiber slip ring also have the limitation of the number of channels. The more the number of channels, the larger the size of the slip ring, and it is difficult to meet the demand for miniaturization of modern products.