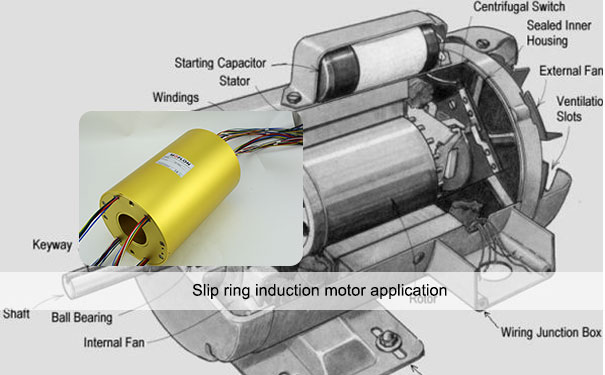

A slip ring is an electromechanical device which helps in the transmission of power and data from a stationary device to a rotating device. It can be used in any form of a mechanical system which requires an unrestrained, continuous or intermittent spinning, at the same time transferring data signal or power.

Thus, a slip ring helps to improve the mechanical performance by simplifying the operations of a system and also removes the dangling wires that come from the movable joints which are basically prone to damage.

Factors considered for the manufacturing of slip ring

There are a number of factors that need to be considered for the manufacturing of a slip ring. Based on those factors, the manufacturer makes these devices which are then used accordingly in different types of machines. The function of slip rings highly depends on the type of it. A spinning electrical slip ring binder is provided for the long-lasting performance which is manufactured with such a technology that it requires a minimum maintenance. It can provide a great compatibility with that of an induction motor slip ring.

Uses of slip ring in induction motor

There are a number of uses of the slip ring in the induction motor. It is due to the high compatibility of the wound rotor motor that the starting torque requires a huge load. For a low current starter, it requires a suitable flow of current which can be provided by the same rotor.

The slip ring is very much suitable for the highly required inertia loads, which may otherwise result in a huge loss of current. Thus, a slip ring induction motor can alter the flow of the current. Also, it can be an extremely reliable device for high loads that are required in a sudden start-up of the torque.

Other than that, the induction motor slip ring can be trusted for a various number of machines which include conveyors, cranes, compresses, elevators, large ventilating fans, hoists, and pumps.

An Induction motor generally requires a low starting torque in comparison to the dc series motor. There is a great advantage of using a slip ring induction motor which requires a high starting torque. Hence, the use of the slip ring induction is highly employed for a heavy load requirement that can supply enough power for a better speed control.

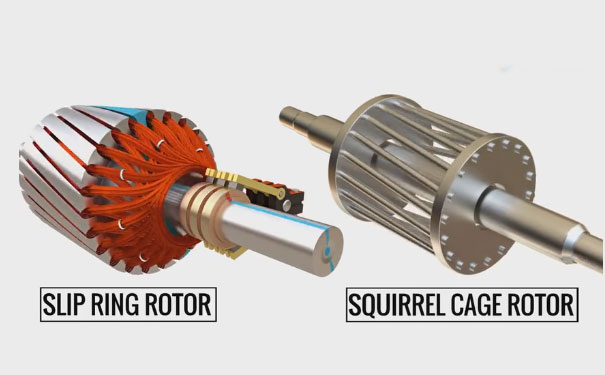

Slip ring induction motors or wound rotor has the benefit which is easier to start and rely on than that of squirrel cage induction motor. By applying resistance in a series with the help of rotor windings, the current at the starting can be set low at the same time maintaining the start of the torque. With the acceleration of the motor, the power of resistance reduces until it reaches full speed and again to zero.

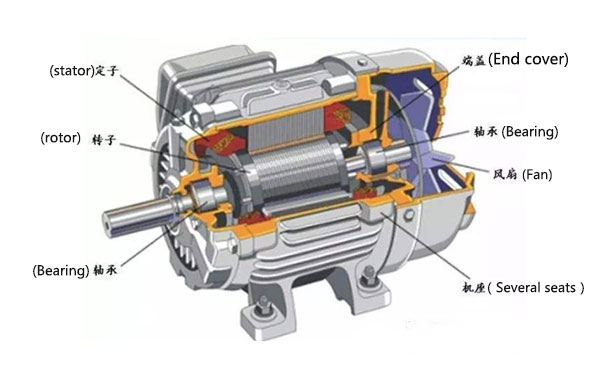

For an induction motor slip ring, both the stator and the rotor have the three-phase windings. This leads to rotor winding being brought to three different slip rings. Therefore, the application of the induction motor slip ring. It is, therefore, mainly applied where a high starting torque and braking torque are required.