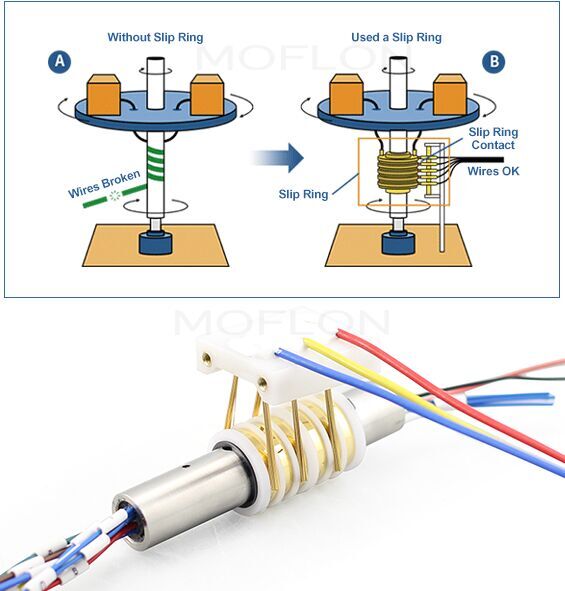

In the electronics industry, the slip ring is used for the purpose of supplying the power and signal from the stationary body to the rotating structure. It is an important metallic part without which the motors or the machine will not work. Before jumping into how a slip ring connector functions, let's understand how a slip ring functions.

A slip ring is an electrical transmission device that transfers energy between one stationary and one rotating component. It is widely used in machines starting from a back massager to the power generator and bulldozer. In the present day, we have numerous machines that power our civilization, and most of those machines are provided with mechanical strength by rotating motors which help in the functioning of those machines.

Motors are essentially rotating devices that produce mechanical energy, and in order to transmit energy to those rotating devices, slip rings are used. A stationary source touches the rotating shaft, and transmits energy to the motors conveniently.

Slip rings are often made of electrically conductive materials, such as copper and fitted to the shaft of a rotating motor with connective wiring going into the motors from them. The component which transmits the energy to the slip ring is called a 'brush'; it is often made with a mixture of carbon and copper and constantly touches the slip-rings, hence the name 'brush' as they constantly brush against the slip-rings. This constant touch conveys the energy flow.

.jpg)

Role of a slip ring connector

To function the machines, a slip ring connector is required to join the static part with the rotating shaft. It is sometimes also called as a rotary joint. Its main function is to transfer the data signal and current through the connector smoothly.

The rotary connectors are found in the AC, wind turbines, electrical generators, and other electronic gadgets. A slip ring connector is useful for transferring power, controlling circuits, and transmitting digital signals of the heliostats, radio telescopes, or rotating tanks.

A slip ring assembly helps the rotor body to connect the sensors to the stator body. In this method, the transmission of data signal and power is supplied through the rotating structure.

Due to the simplicity of the assembly, it is mostly used for communicating and powering the PLCs. The automatic equipment factory and the robot manufacturer also use the slip rings for its unique features.

The distinctive characteristics of the assembly are:

1)Some of the slip rings are tubular in shape.

2)The assemblies are made of waterproof technique.

3)Most of the rings are light in weight.

4)The bearings of the slip ring are smooth in nature.

5)Different types of models are available.

Motor slip ring

The slip rings are also referred to as motor slip ring as these are used in the motorized machine. These rings have better winding power than the regular ones. It has the higher voltage and low current. As the motor peak up speed, the power and signal reach to the stationary body. The motor rings have high resistance power.