The most basic function of slip ring which is to transmit the signal from the rotor to the stator is quite an established fact. It is this basic functionality of the slip ring which has paved way for multiple application of the slip ring in the core industrial fields and its periphery. The slip rings bring an added advantage of transmission using the mechanical parts without interfering the 360-degree rotation of the device at hand.

The slip rings are also potent enough to transmit all kind of signals. In fact, it is the wave of technological process that has made the slip ring manufacturer come up with an advanced form of slip ring which exceeds the general conventions of transmission requirement. Just to validate the validate the aforesaid point, we can just pick any form of the modern slip ring. In this case, if we consider ethernet slip ring, say a decade ago the need for transmission of high-frequency data signal was rare, but with more form of communication equipment being introduced in the scheme of thing. The need for high-frequency data signal became a mandate. Thus, the introduction of Ethernet slip ring was quite natural.

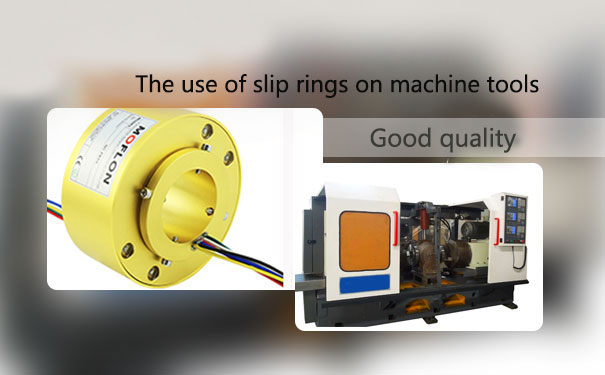

Application of slip ring in the heavy duty application

The current lot of slip rings is ideally built to fit the situation under which the heavy-duty equipment operates. When we industrial application we need to take into taking into account the harsh condition under which they operate. The way to achieve operational efficiency in such tough conditions depends on the quality of the slip ring. By quality of slip ring, we necessarily mean the kind of shielding material used and the quality of the slip ring contact material. The operational efficiency in the industrial slip rings has to do more with the shield and the insulating material used. In some cases, the operational speed should also be monitored and increased up to the required level.

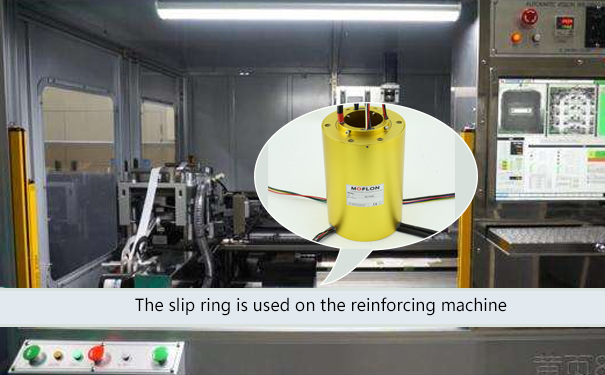

Communication of data signal in industrial equipment

The whole deal with using the slip ring in the industrial field is not just about the rotational speed and the shield. This is a contradictory statement to the above idea of shield and insulation, but this is done to highlight the fact that the way to achieve the maximum output in the industrial production channels, the need for transmitting the power signal is just as important as other key factors. In the initial days, for the transmission of data signals in the production line equipment cable wire were used but with the passage of time slip ring began to be used increasing and the inclusion the latest slip ring technology was the pivotal point as the level of output derived from the conventional slip ring increased manifold. And it is just a matter of time that with the further advancement in slip ring technology, the range of its application in the industrial might just expand exponentially.