Using a productive slip ring for the wind turbine can improve the operational performance of the machine. The wind turbine slip ring if not maintained properly will not function in the desired manner. This will not be cost effective for the wind farm owners owing to the costly replacement and untimely repairs.

The slip rings transfer the current to the motors in a turbine's blades and it sends back the data signal to the hub from the blades sensors. Working in the harsh atmosphere can cause rust formation and accumulation of debris in the slip rings. Therefore, a proper maintenance of the wind turbine slip ring will extend its lifespan.

Some of the maintenance tips will help the wind farm owners:

1)Inspect the damage: Check the slip rings and brushes regularly to check whether there are wears and electrical damage or not.

2)Dust accumulation: Slip rings will not transmit power if there is dust accumulation. So, use the compressed air vacuum system to clean the dust.

3)Leakage of fluids: Leakage of water or oil can cause malfunctioning of the wind turbine. Accumulation of sand or operation in a humid region can also affect the functioning of the slip rings. Use special kind of brushes available to remove dust and clean the sand or leaking oil and the slip ring will give optimal performance.

4)Time to time replacements: Change the metal brushes of the slip rings to avoid the future inconvenience. Worn out brush will not be able to contact with the slip rings. Replacement is a good idea to enhance the performance of the brushes.

5)Regular maintenance: Regular maintenance and inspection will save you from the costly repairs. This will keep wind turbines in order.

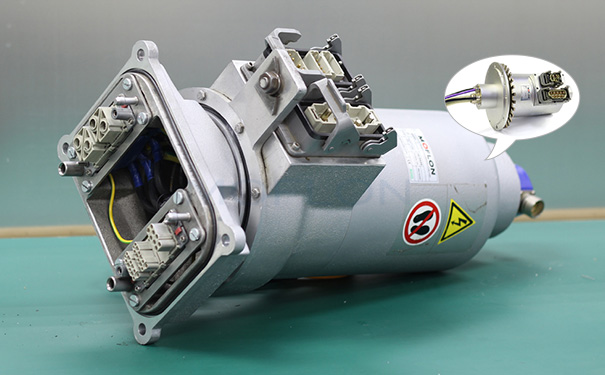

Slip rings and brushes

After having discussed about slip ring and brushes. We will discuss today the export sales of these products in the international market. Both the slip rings and brushes have huge popularity in the international market and not just the domestic market. The development of the products has increased as it had gained huge export sales volume.

In China, numerous companies produce the slip rings and brushes. Their production has a demand in the global market. The reasons behind this growth of development and export sales are the kinds of raw materials used for the products, the scientific techniques applied, the specific requirements and the quality of the materials. The user's reference and standard quality have increased the sale in the international regions. The slip ring and brush have the traits to meet the requirements of the world's industries.

Some slip ring companies provide free sample to the customers for recommendations. Other companies choose the promotion way through the network channels. Besides, every year the slip ring manufacturers participate in the trade fairs organised in each country. They exhibit their production material at the fairs. Customers visiting the fairs inspect and observe the materials. Hence, slowly each year the export sales of the slip rings and brushes have increased in both the domestic and international markets.

In today's age, every industrialized and mechanized unit need slip rings for the machines and equipment. The slip ring CT helps to rotate the devices and the quantity of production depends on the quality of the slip ring. In general, it is a conductive slip ring and sometimes referred the collector ring.

The main principle behind the working of a slip ring is the transmission of parallel electrical energy and signal to the stationary and rotating machines. It is widely used in many industries for many factors like:

1. Smooth functioning: The ct slip ring runs smoothly in 360-degree.

2. Long lasting: The metal wire used in this product ensures the long duration of the material.

3. Reliable product: The fiber brush technology makes the product more stable and reliable.

4. Compact structure: The component structure is compact and thus, provides high performance.

5. Protective material: It is made up of quality materials and produces very low noise.