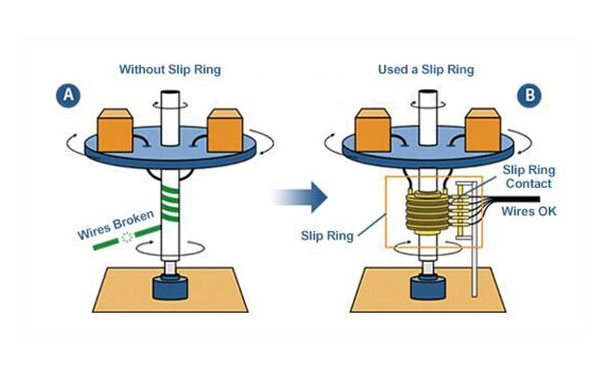

In any testing environment, which has challenges related to the thermal variation. The need for thermocouple comes into the scene. Having said that, the application of correct slip ring is also as necessary as introducing a thermocouple. It is the slip ring which goes a long way in assimilating data and at the same time, it is the thermocouple which manages the temperature changes at the first place for the proper functioning of the slip ring. Thus, it can be said that the appropriate combination of slip ring assembly units and the thermocouple helps to gather relevant data with minimum error.

Functioning aspect of thermocouple

The thermocouple consists of two dissimilar conductive wires which are connected at one end and the point of contact is called the junction. The thermocouple requirement changes the thermal differences or the heat differences in the component through which the current flows. The level of voltage flowing through the unit is also a crucial factor here, in tackling the thermal variation. This is due to fact that the Voltage/temperature ratio is sensitive to the kind of conducting wire used.

The voltage level of the wire cannot be measured directly from end to end. So, in order to ascertain the level of voltage, a distinct conductive wire can be introduced at one end. The next step is to measure the difference in the level of the voltage that flows through the unconnected wires joined at the other end or junction. Also, a source thermally induced voltage needs to be introduced at the opposite end of the junction.

Installation of the thermocouple with reference to the slip ring stator and the rotor

When we deal with the iron-constantan thermocouple an addition of copper in the lead wire will alter the level of differential voltage. The variation level of the differential voltage is confirmed with the use of readout display instrument attached at one end. But the variation is only possible when there is a change in the level of temperature in the different ends of the copper insert. Having said that, in case if there is no variation in the thermal or temperature level then there is no change in the voltage or the thermal output. So, in cases where the slip ring rotor and the stator have the same temperature level, it is almost certain that there is no error in the data gathered with the inclusion of distinct metal in the circuit.

So, it is quite a clear that only in such cases where the thermal level of slip ring stator and the rotor are not the same, the error in the readings might creep in. So, it becomes quite imperative to comply with the temperature requirement at both terminals the stator and the rotor. Generally, the installation is made in such a way that the temperature levels of the stator and the rotor do not dwindle much in accordance with acceptable measurement limits.