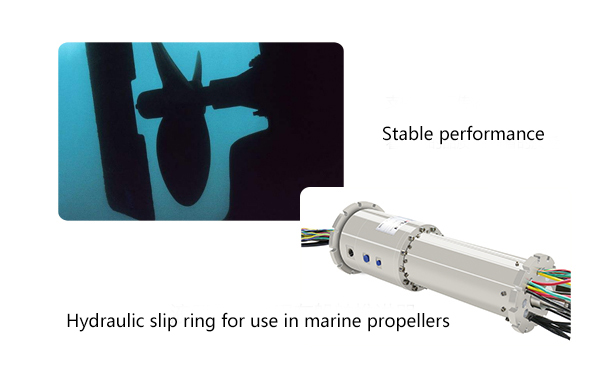

The hydraulic slip rings and the electrical slip rings are the positive outcomes of the efforts that various slip ring manufacturer have put to sustain the relevance of using slip ring in the rapidly progressing technological era. The hydraulic slip rings are ideally used to transmission of liquid and gas-liquid elements. To be precise, it is used for transmission of oil medium from the stationary part to rotating the part. The electrical slip ring is used to pass the current signals from the rotating to a stationary body. Having established the basic distinction between both kind of slip ring, let us look at some of the core aspects of both kinds of the slip ring.

hydraulic slip ring and electrical slip ring similarity

The hydraulic slip ring or commonly referred to as liquid slip ring receives power from the main motor which is attached to the slip ring itself. Considering the usefulness of such slip ring, they help to transmit the fluid medium as a primary source of transmission while the gaseous or liquid-gas form of transmission is the secondary usage of such slip ring. The entire transmission takes under a continuous 360-degree rotation. Although, there are various differences in both form of slip rings which is quite evident, one of the striking similarity between hydraulic slip ring and electrical slip ring is that the whole transmission process takes place without hindering the 360-degree rotational motion of the device at hand.

Structural and fundamental differences between both forms of the slip ring

As mentioned earlier, the element of differences between the chosen slip rings are quite evident and most of the point of disparity is in the way the slip rings are designed, which obviates the differences in components of the slip ring. The liquid slip ring includes the main rotor the source of power for the slip ring, housing, bearing, insulating sheet, external protective shell, certain components of hollow shaft depending upon the customization requirement of the user and finally, it the most integral part of slip ring the carbon brush.

Considering the technical parameters, the hydraulic slip ring functioning depends on certain key factors some of which include rotational speed requirement, count of channels, thermal heat level, and pressure. On the other hand, if we take into account the electrical slip ring the key parameters include resistance, number of circuits, and the voltage level.

The performance aspect of the liquid slip ring maintaining the rotational speed without hampering the flow of transmission medium and the sealing technology used in such slip rings also plays a key role in determining the level of performance.

The key factor which determines the performance the electrical slip ring is the choice of carbon brush, which in the first place makes the transmission of electrical signal possible. Also, the capacity of the brushes to tackle resistance is a key element in determining the performance level.