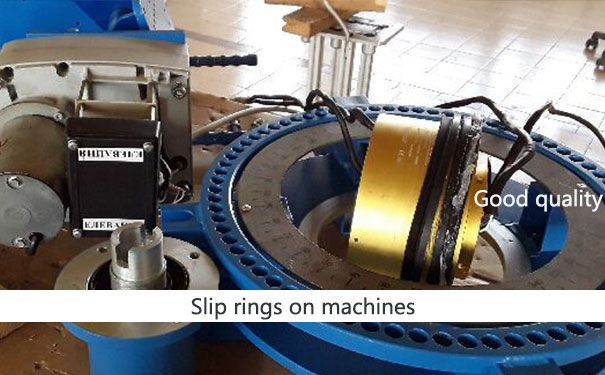

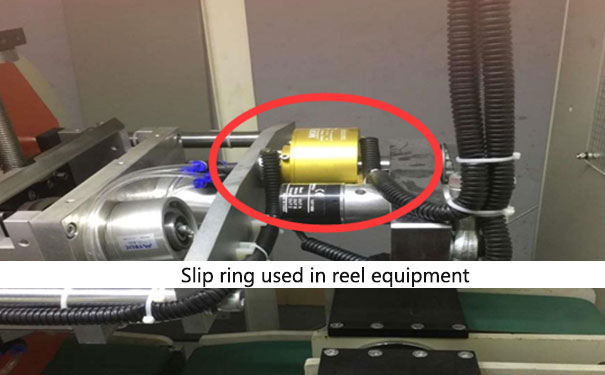

slip rings are basic and one of the most important part or components of any machine which include parts like rotating shaft or any rotatory component. It is in itself an electrochemical device that allows transmission of electrical or other signals from a stationary to a rotating structure. It can be or to be precise 'it is used' in any machine which requires rotation to transmit signals while maintaining the rotation.

They are found in slip ring motors, AC systems, alternators, wind turbines and many other machines. Though it is equally important to state that there are different slip rings which are used in different types of machines that require different form of rotation. Despite all the differences one thing which is common in all of them is that all slip rings in all the machines loses its efficiency during its life or to say is subjected to continuous wear and tear while usage. With this, the paramount question which any user will ask is 'how to increase life of slip rings?' which in turn is going to enhance and even extend the life of the machine which is using it. But to answer this question we should know the different causes which results in malfunctioning or complete halting the working of slip rings.

In rotating shafts where rotational velocity is high, the main cause of wearing of rings is rampant heat generated through friction, which even degrades the quality of signals being transferred.

In this case, to avoid the trouble, the slip ring which is to be used should be made up of material less thermal affinity.

In other case where the reason of failure of slip ring operation is foreign particle like dust and moisture, the care should be given while making the machine itself to make it dust and water proof which rubber or wax coating, and if the design is simple or the machine can be dissembled easily then time to time cleaning of the rings is must.

In places where the daily duration of usage of slip rings is more than average, the brushes must be replaced on routine basis to ensure maximum efficiency of the machine and the rings.

Apart from all these tips, the utmost importance should be given while designing the slip rings or the machine itself. Different types of machine are designed for different purposes. Some of them use slip rings only for the transmission of electric current and some covert them into other signals afterwards. A good engineering always ensures the prolong functioning of the machine. A good habit is that the brushes of rings which has minimal cost should be replaced time to time, this also reduces the chance of failure of the whole body of slip ring in future.

The alignment of slip rings also plays an important role in understanding the question. In vertical hanging slip rings configurations need to be different to ensure that the signal channels remain above the labyrinth seals.

With horizontally mounted slip rings, gravity neither help nor hurt the situation much. The configuration can be made in any desired manner. In this case the evils are dust and moisture. Overall, it is to be summarized that slip rings though constituting a small part in the entire machine plays main role of transferring signals while maintaining the rotation. And in rest the slip ring itself constitutes the whole machine.