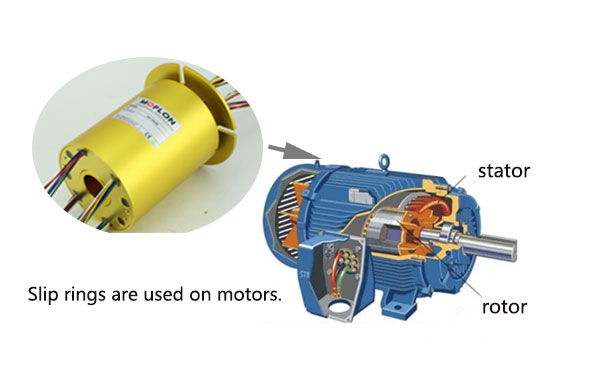

We generally have observed the use of the use term phase wound rotor synonymously with slip ring motors. Now the question is why are they used in such a manner, well the answer is that the slip ring motors itself include phase wound rotor which is the component of any such equipment. We can put it this way a slip ring motor ceases to exist if the phase wound rotor is missing from the setup, period.

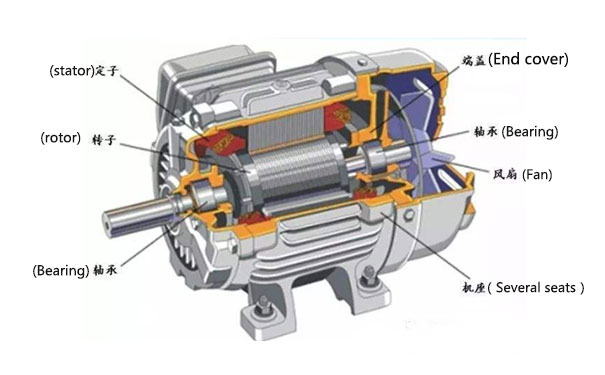

Components

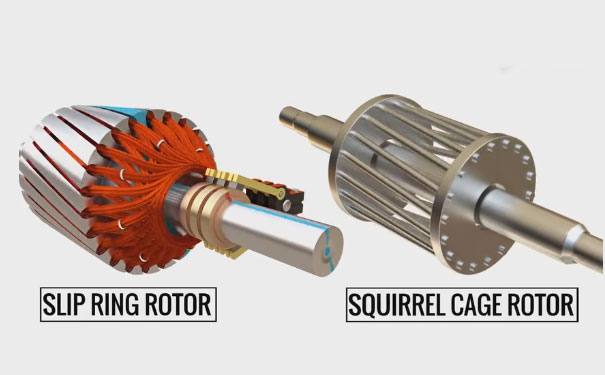

The phase wound rotor generally consists of windings of coils that are quite frequently used in alternators. The wires are wound in three phase and distributed evenly across channels with proper insulation.

The slip ring rotor or the three-phase wound rotor at the core is formed using a steel lamination which is pre-designed with three slots to fit in the phase windings.

The slip induction motor can be ideally defined as a standard a synchronous motor. The reason for such comparison is the fact that the in case of the equipment at hand the rotor and not functioning synchronously. To be precise it is the rotor which does not operate in sync with the stator.

Construction of a slip ring induction motor

The construction of any kind of slip ring induction motor depends mainly in the design pattern of the rotor and the stator that is to be fitted in any system.

The slip ring induction motor application mainly is based on the way the rotor and the stator are brought together as one unit in the entire setup, we will begin with understanding how a stator is added to the slip ring induction motor.

Stator and rotor

The squirrel cage mirror and the floor in induction motor have quite a considerable similarity in their construction pattern. The only difference which can be sighted in the stator is in terms of its usage in unison with the rotor.

The changes in the construction of slip ring induction motor are quite prominent in situations where the slip ring motor is used in the cascaded system. The reason why there is a change in construction pattern is that the slip ring motor used in the cascading system includes a slave motor which gets its power supply from the rotor in the master or main motor. Also, in such case, the external resistance is introduced in the system through the rotors.

As mentioned earlier, the rotor in the will ring induction motor are usually to as the phase wind rotor. They are available in three phase form with wound cable wiring which is insulated and evenly distributed. But the interesting part is that the rotor is wound to fit and equal in pole when compared to the stator.

The three wound wires are generally are stacked internally at one end, but the other end other wires are connected to the slip rings in unison with the brush gear system and entire set up is held together with the slip ring assembly.