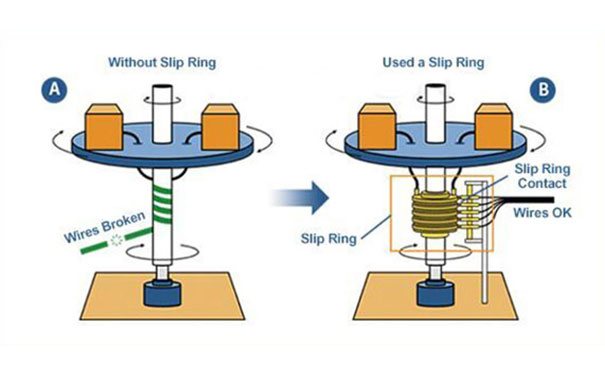

The generic definition of slip ring brings the functionality aspect of the slip ring to the notice. But how does the slip ring in the first place achieve this sort of functionality or simply how does the slip ring make way for transmission of signal and power? It is something that has for long been the source of curiosity when we talk of the slip ring. So, before getting it he details of how do slip rings work? We need to understand the definition and the components of the slip ring. Thus, let us begin with the standard definition of the slip ring.

According to the standard definition of the slip ring, we can perceive it (slip ring) as an electromechanical device which helps to transmit a different type of signals (based on the kind of slip ring used) form the stationary part to a rotating structure. As mentioned earlier, we can figure out the function of the slip ring, but the real deal is understanding how it actually works. Now let us get a bit closer in understanding the working aspect of a slip ring by first learning about the different components of slip rings.

Different components of the slip ring

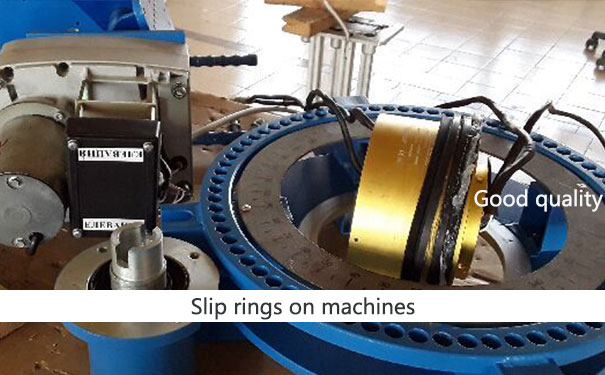

To understand the working of a slip ring we need to first acquaint ourselves with two important components of slip rings. The first is the conductive ring and the second is the brush. The ring is an integral part of the device which at the first place conducts power and signals. While the brush is the one which makes the connection possible through contact which is commonly referred to sliding contact.

The working of slip rings is ideally based on the sliding contact between the slip ring and brush. The brushes rub against the conductive ring which allows the sliding contact to take place. The brush component of the slip ring is generally stationary while the conductor rings form the rotating part. The lead-based wires are internally connected to the brush and the conductor ring. The rings are mounted on the rotor shaft and connected the wires. The brush is held tightly in position with the brush holder and is mounted on the housing.

The working if the slip ring can be summarized in the following manner as the ring begins to initiate its rotational motion, the brush rubs against the surface of the ring which cause the ring to rotate at an accelerated speed and as there is an increase in rotational motion, the ring beings to transmit the data and power signals through the lead wires.

As the primary function of the slip ring is to conduct the electricity and power signals they are generally made up of quality conductive materials. The choice of materials depends on the current load that load that needs to be handled by the system, rotational speed requirements, voltage requirements and resistance of the system at hand.