Induction motors are classified into Squirrel cage and slip-ring induction motors according to the type of motors used in them. However, squirrel cage induction motors dominate the user market.

Squirrel cage motor:

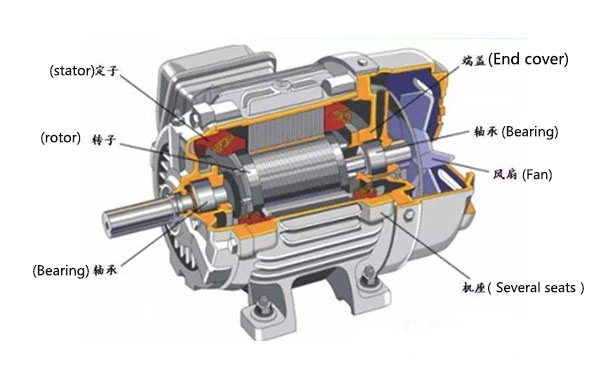

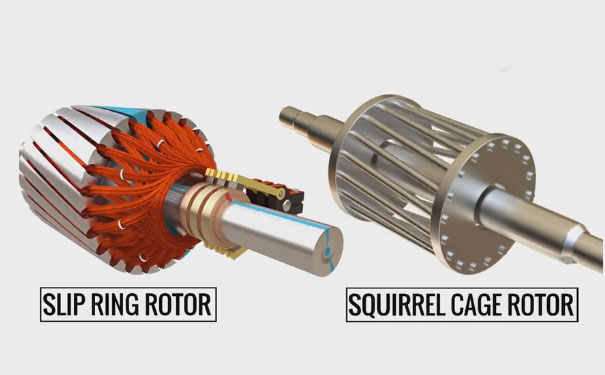

It has a rugged and non-complex construction consisting of a rotor with a laminated core (Cylindrical) that has half- circular slots. Each end has a short circuit by using copper or aluminum ring or short-circuiting ring. Squirrel cage motors are characterized by the absence of external resistance connected to the rotor.

Advantages of having skewed rotor:

Rotor slots in a squirrel cage motor are skewed, advantages of which are the following:

.It reduces the magnetic hum, thus keeping the motor quiet.

.Skewed rotor provides smooth curves of torques for all rotor positions.

.It avoids Cogging, i.e. locking tendency of rotor and stator.

.It results in a high ratio of transformation between a rotor and stator.

.The rotor resistance is increased.

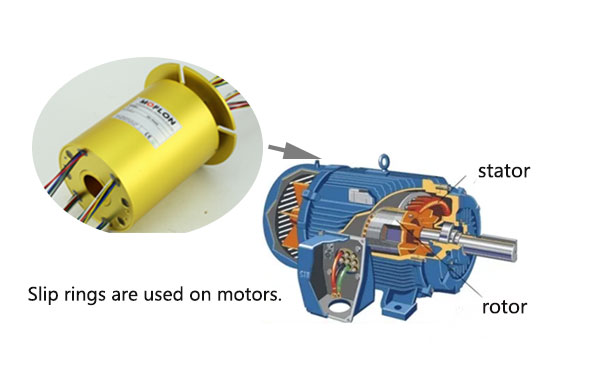

slip ring motor:

Slip ring motor is also known as phase-wound motor since it employs the wound rotor. A Slip ring motor comes with laminated cylindrical cores along with semi-closed slots at the boundary to include three-phase windings. The rotor is wound for the same number of poles as in the stator and the free end of these windings are connected to three insulated slip rings fixed on the shaft. Carbon brushes touch the slip rings with the help of a slip ring assembly. These brushes are connected to an external rheostat.

Important differences between squirrel cage and slip ring induction motor:

.External resistance: The key difference between the slip ring and squirrel cage motors is that a slip ring motor contains an external resistance which increases rotor resistance and thus, the starting torque in it. However, a squirrel cage motor cannot contain any added resistance circuit because the bar is slotted permanently.

.Rotor: Squirrel cage motor has a squirrel cage type of rotor with skewed slots, while, a slip ring motor comes with a wound type of rotor with parallel slots, each containing one bar.

.Construction: A slip ring motor gest a complex construction owing to the use of slip rings and brushes, whereas, squirrel cage motors are simply-built.

.Starter: Rotor resistance starter may be used in a slip ring motor but not in a squirrel cage motor.

.Starting torque: Slip ring motor needs a high starting torque as opposed to a squirrel cage one.

.Copper loss: Copper loss is low in squirrel cage motor in comparison to slip ring motor.

.Efficiency: Slip ring motors have lower efficiency than squirrel cage motor.

.Speed control: Speed control is possible in slip ring motor with the help of an external resistance circuit. However, controlling the speed of a squirrel cage motor is not possible.

.Maintenance: The maintenance cost of a slip ring motor is high since it contains brushes.

.Uses: Slip ring motors are used in places requiring high starting torque. On the other hand, squirrel cage motors are used in lathe machines, fans, blowers, etc.