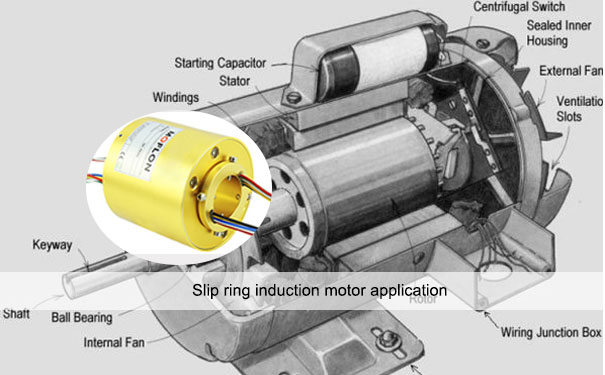

A slip ring motor is comprised of two distinct parts, a stator, and a phase wound rotor. A wound rotor motor has its rotor windings connected to an external resistance through slip rings, which ultimately aid in regulating the torque of the motor. Although, the stator of a slip ring motor resembles its squirrel cage motor counterpart, the construction of its rotor is quite different.

Qualities of a slip ring motor:

.Slip ring motors can generate high initial torque without providing much current. Hence, it is suitable for high inertia loads.

.Slip ring motors require comparatively low starting current than the squirrel cage motors.

.External resistance, connected to the windings of the rotor, helps in varying speed.

.This type of motor calls for high brush and slip ring maintenance.

.Wear and tear of the brush lead to unrequired friction.

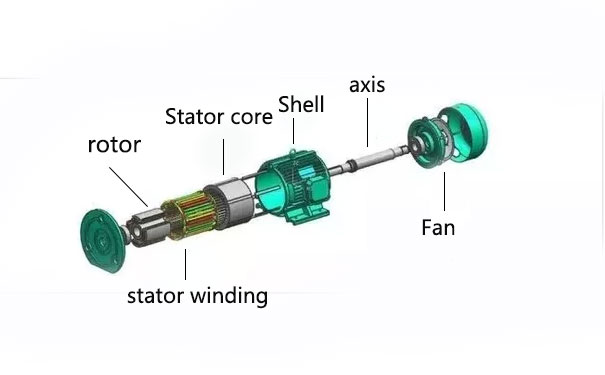

Construction of a slip ring motor:

Stator: The stator is the outer, visible part of the motor. The three-phase windings are placed 120 degrees apart on a laminated core, as either star or delta.

Rotor:

.The phase-wound motor generally used in slip ring motors, has a 3-phases and double-layered winding.

.A rotor core comprises of steel laminations with slots to include three single phase windings, each placed at a distance of 120 degrees.

.Rotor is wound thrice, and the free end of each windings is connected to insulated slip rings on the shaft.

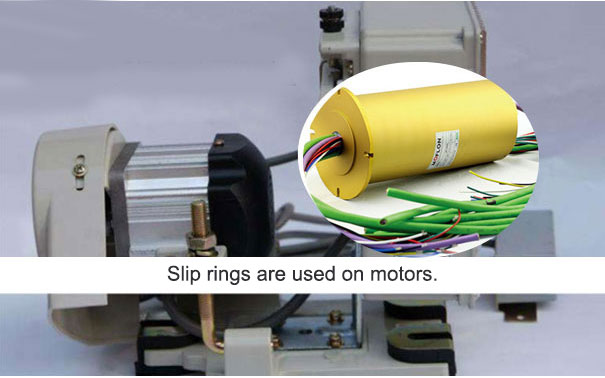

.Carbon brushes are arranged to touch the three slip rings via a slip ring assembly.

.These three brushes are connected externally to the star connected rheostat.

.The external rheostat allows added resistance in the rotor, enabling it to have higher current and thus higher torque.

.During normal conditions, the three slip rings, followed by the three-phase winding are short-circuited by this arrangement and end up behaving like a squirrel-cage induction motor.

.Under short-circuit, the carbon brushes automatically lose contact with the slip rings to prevent friction.

.Slip rings are made from high-quality phosphor bronze.

Working mechanism:

.As opposed to the squirrel-cage induction motor, the current is low, starting rotor resistance is high, and the initial torque is set to the highest point.

.The slip required to create highest torque is proportional to resistance of rotor.

.High rotor resistance leads to more slip and finally, pull-out torque at low speeds is achieved.

.With accelerating speed of the rotor, the external resistance is reduced and the winding short-circuited.

.The motor's operational efficiency is increased when resistance decreases.

.The external resistance should be designed so as to vary the speed of the motor between half to full of the rated speed.

Benefits of slip ring motors:

.The key benefit is the fact that the speed of slip ring motor can be varied according to our need.

.Slip ring motor has high starting torque, around 200% to 250% of a squirrel-cage motor full load torque.

.This motor takes only 250-300% of the load current as starting current.