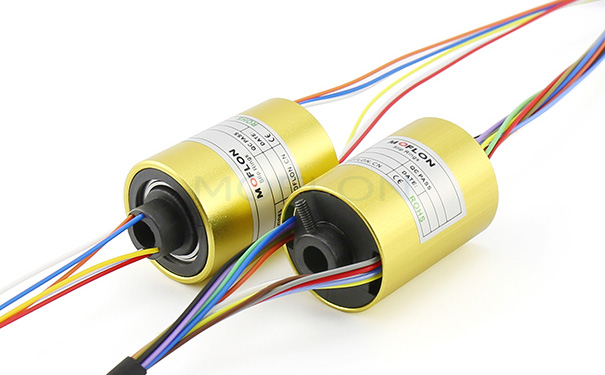

The electrical slip ring assemblies are generally mounted on the center of rotation between the stationary and the rotating components of any given equipment. In most cases, there are fluid and different types of signals that are to be transmitted between the stationary and rotating parts. Thus, for this very purpose, the need for a rotary joint arises.

Functioning essentials of multiple rotary joints

In such a situation when there is more than one type of rotary joints mounted on the centre of rotation. It is quite imperative that slip ring wire must pass through the center of other units like a hydraulic rotary swivel or union or the hydraulic lines itself must pass through the center of the slip ring.

slip rings wires and lead bundles

Slip rings with a specific design for up to 14" through bore can be employed to cater to the needs of a high percentage combination union of a rotary union application. In cases where the slip ring wires or leads are combined with the hydraulic swivel. The slip ring wires and lead bundles being much smaller than hydraulic hoses makes the approach of passing the electrical leads through the center of the hydraulic union economically viable. In the aforesaid situation, the centre bore size is increased and therefore the overall diameter of the slip rings to be employed can be cut down, which ultimately brings down the cost of the slip ring portion of the entire assembly.

There are a variety of other applications that function in the desired manner when there are more than just a single air passage. Besides, the hydraulic and electrical swivel unions. The need for introduction of more air passages depends on the size of air lines required in the system. There are various research and product development taken up by the companies to bring an advancement in the slip ring technology in this respect.

Custom Designed rotary swivel units

The custom designed two and four rotary pneumatic swivel units have plenty of additional features. Such kind of units entail tailor-made brass construction designs and two or four ?" NPT ports for control type-air lines. The brass swivel unit which is mentioned above is also used with other gases and fluids., which ordinarily require different kinds of the material seal between the air passages. Both the wiring harness and the air swivel line passes through the centre hole of the hydraulic swivel, when stationed together with a slip ring center harness. With the application of newer designs, things get a bit simpler and economical as the pneumatic swivel unit can be removed without actually removing either the slip ring or the hydraulic swivel unit. It should also be noted that the same kind of design-queue is involved in joining the fibre optic rotary. There are various companies in the past that have undertaken the burden of customising slip ring and it is good to see the trend continuing as more and more companies are willing to invest in research and development projects of slip rings.